- Mail Us

- info@alaskapuf.com

- Call Us

- +91-814-143-3999

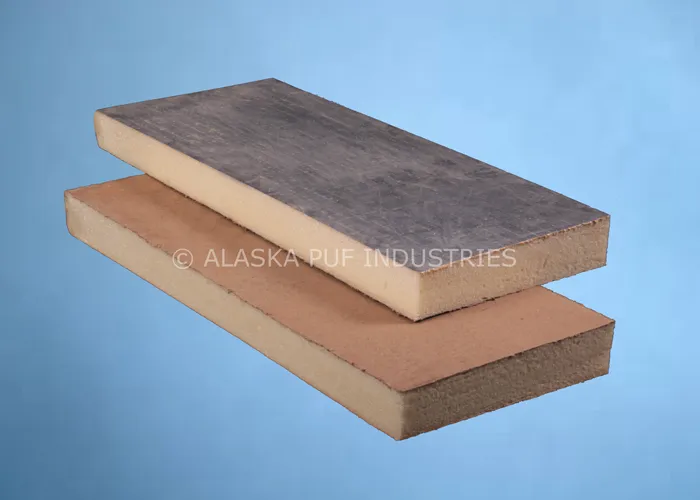

Laminated PUF/PIR Pipe Section & Sheet

Why Choose Alaska Puf

We have a 14000 Sq. Feet of Hi-tech manufacturing unit comprising following machines

- 2-axis CNC cutting machine with 2500mm x 1200mm x 600mm (LWH) bed size– 3 Nos.

- 3-axis CNC Router machine with 2500mm x 1200mm x 300mm (LWH) bed size

- HP60 PUF/PIR chemicals dispensing machine

- HF1600 High pressure PUF/PIR chemicals dispensing machine for PUF spray and in-situ

- 12feet x 6feet wide hydraulic press

- Chiller machine for chemicals

- Vertical block cutting and PUF support cutting machines

- Various size of molds for PUF slab and pipe supports.

- Bag filter with 9bag system for waste collection

- Crushing & mixing machine for PUF recycling

- Multi-racked storage system

FAQ About PUF / LAMINATED PUF

-

What is the maximum temperature resistance of laminated PUF/PIR pipe sections and sheets?The maximum temperature resistance of laminated PUF/PIR pipe sections and sheets is typically up to 140°C.

-

What is the advantage of laminated PUF/PIR pipe sections and sheets compared to non-laminated ones?Laminated PUF/PIR pipe sections and sheets have an additional layer of protective coating, which makes them more resistant to environmental factors and physical damage.

-

Can laminated PUF/PIR pipe sections and sheets be customized to specific sizes and thicknesses?Yes, Alaska Puf Industries can manufacture laminated PUF/PIR pipe sections and sheets in custom sizes and thicknesses to meet the specific requirements of clients.

Enquiry Now

Scan the QR to call