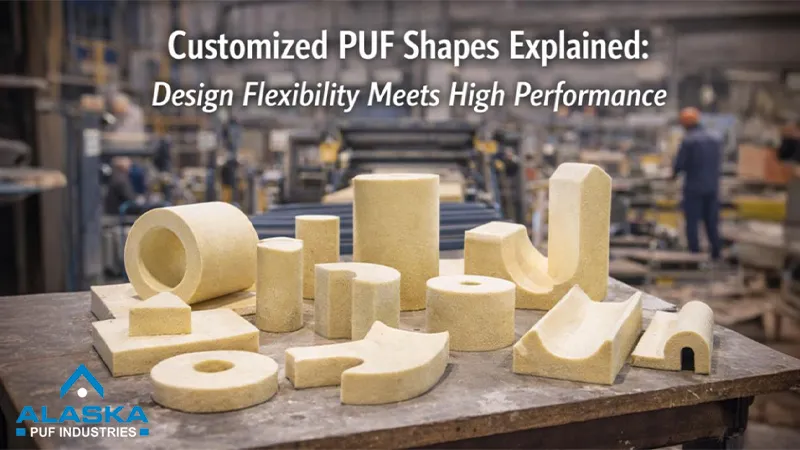

In today’s fast-evolving industrial landscape, insulation and structural efficiency play a critical role in product performance and long-term reliability. From cold storage facilities and cleanrooms to HVAC systems and specialized construction projects, materials must adapt to complex designs without compromising durability. This is where Customized PUF Shapes stand out as a transformative solution. By combining flexibility in design with outstanding thermal performance, polyurethane foam (PUF) shapes have become a preferred choice across industries.

At Alaska PUF Industries, innovation meets precision manufacturing to deliver high-performance Customized PUF Shapes tailored to specific project requirements. As one of the trusted Customized PUF Shapes Manufacturers in India, the company focuses on delivering engineered solutions that align perfectly with architectural and industrial needs.

Understanding Customized PUF Shapes

Polyurethane Foam (PUF) has been well known to have excellence insulation qualities, light weight, and the ability to withstand mechanical forces. But nowadays, it is something that cannot be satisfied only with standard panels or blocks. They need intricate shapes, rounded areas, filler pieces of the cavity and molded parts of particular size. PUF Shapes Customized PUF Shapes are pre-engineered foam products, which are made to specifications. These may be shaped, sliced or engineered into different profiles including cylindrical sections, trapezoidal blocks, curved panels, duct supports, sections of pipe insulation, and structural cores. Compared to conventional insulation products, Customized PUF Shapes enable designers, engineers, and manufacturers to realize complicated designs and retain thermal performance and structural integrity.

Why Design Flexibility Matters in Modern Industries

It is rarely the case with industrial and commercial projects that have a uniform design. Cold storage rooms need corner installations, HVAC systems must have accurate duct insulation pieces, prefabricated buildings must be based on structural cores that fit precisely. Customized PUF Shapes allow manufacturers to establish a solution of insulation that is compatible with complex layouts. Flexibility minimizes the gaps in installations, lowers thermal bridging and boosts the efficiency of the entire system. Being good and seasoned Customized PUF Shapes Manufacturers, firms such as Alaska PUF Industries come up with personalized solutions that are seamlessly integrated into various project set ups. Design flexibility is a contributor to:

- Accurate fitting for complex geometries

- Reduced on-site modifications

- Improved structural compatibility

- Enhanced thermal and acoustic performance

High-Performance Thermal Insulation

Customized PUF Shapes has one of the greatest strengths in its ability to insulate. Polyurethane foam has a closed-cell type which limits heat conduction. This aspect makes it suitable in cold chain logistics, refrigeration storage, and temperature sensitive places. In a move to offer insulation solutions that will meet the needs of the project in terms of temperature control, Alaska PUF Industries is able to offer customized solutions by making the Customized PUF Shapes which are customized owing to their specific density and thickness. Being one of the top Customized PUF Shapes Manufacturers in India, the company has an emphasis on achieving credible performance of insulation under different climatic conditions. The effect is increased energy efficiency, reduced operation expenses and reduced internal temperatures.

Structural Strength with Lightweight Composition

Polyurethane foam though low in weight has impressive compressive strength. This is the strength weight combination that makes Customized PUF Shapes applicable in structural support needs where both load bearing and insulation are required. In prefabricated buildings and industrial assemblies, the custom-shaped PUF cores provide stiffness without excessive weight. Being the established Customized PUF Shapes Manufacturers, the Alaska PUF Industries produce components that retain their dimensions and mechanical integrity despite the challenging conditions. Such structural reliability strengthens life and performance at industrial installations.

Energy Efficiency and Cost Optimization

Energy consumption remains a major operational concern for industries. Poor insulation leads to higher energy usage, increased costs, and inconsistent performance. By incorporating Customized PUF Shapes, facilities can significantly improve thermal retention. The ability to match insulation precisely to structural geometry reduces energy loss through joints and irregular spaces. As established Customized PUF Shapes Manufacturers, Alaska PUF Industries contributes to long-term operational savings by delivering components that improve energy management and thermal reliability.

Sustainability and Long-Term Performance

One of the considerations in contemporary construction and industrial planning is sustainability. Long life insulation material lowers maintenance and replenishment rate of materials. Individual PUF Shapes have a long service life, are resistant to moisture intrusion, and stable thermal properties throughout the service life. This is due to their durability making them applicable in projects that require solid insulation in the long run. Alaska PUF Industries is one of the reliable Customized PUF Shapes Manufacturers in India, which develops solutions that are in line with the changes in the industry and environmental factors.

Why Choose Us

Alaska PUF Industries is unique in its technical accuracy, reliability of products, and customer-oriented production. The company has a long history in the industry, and it knows that every single project is a challenge and needs a different approach to insulation. With a combination of high-technology fabrication techniques and thorough analysis of projects, Alaska PUF Industries provides Customized PUF Shapes, which meet the specifications and the expectations of the project design perfectly. Being among the reliable PUF Shapes Customizing Manufacturers in India, the company focuses on the quality of materials, correct sizes, and reliable delivery schedules and is thus a good choice of partners by companies that need high-performing Insulation materials.

Conclusion

Customized PUF Shapes represent a powerful combination of design adaptability and thermal performance. Their ability to conform to complex geometries makes them ideal for industries that demand precise insulation solutions. From refrigeration and HVAC systems to prefabricated structures and specialized equipment, these tailored components contribute to energy efficiency, structural stability, and long-term reliability. Alaska PUF Industries continues to lead as one of the respected Customized PUF Shapes Manufacturers in India, delivering engineered solutions that match modern industrial demands. By prioritizing precision manufacturing and material performance, the company supports projects that require both flexibility and dependable insulation outcomes.

For expert guidance on Customized PUF Shapes Call +91 8141433999 or email info@alaskapuf.com.

Key Takeaways

- Customized PUF shapes provide design flexibility, allowing precise insulation for complex geometries in cold storage, HVAC, and prefabricated buildings.

- They deliver high-performance thermal insulation with closed-cell polyurethane foam, reducing heat transfer and improving energy efficiency.

- Lightweight yet strong, customized PUF shapes offer structural support while maintaining mechanical integrity and dimensional stability.

- Properly fitted shapes minimize energy loss, lower operational costs, and optimize overall system performance.

- Durable and moisture-resistant, customized PUF shapes ensure long-term reliability and sustainability in industrial and construction projects.