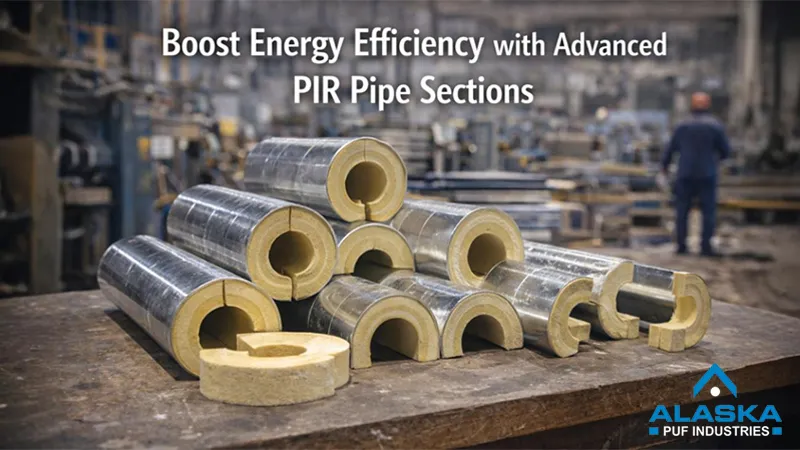

In today’s competitive industrial environment, energy performance has become a defining factor in operational success. Industries across oil and gas, HVAC, pharmaceuticals, chemicals, food processing, and power generation demand insulation systems that deliver thermal stability, durability, and long-term cost savings. One of the most efficient insulation solutions available today is PIR pipe sections. With advanced manufacturing standards and precision engineering, Alaska PUF Industries delivers high-performance PIR pipe insulation designed to elevate energy performance across applications.

As industries continue to seek sustainable and cost-effective insulation materials, the demand for PIR Pipe Sections Manufacturers in India has grown rapidly. Businesses are prioritizing solutions that reduce thermal loss, improve process stability, and enhance safety. explores how advanced PIR pipe sections contribute to superior energy performance and why they are becoming the preferred choice across industries.

Understanding PIR Pipe Sections

Polyisocyanurate (PIR) is a thermoset material that is characterized by very high thermal insulation qualities and structural integrity. PIR pipe sections are ready-made insulation pieces that are meant to be placed around the pipes, preventing heat transfer with the resultant temperature control in both warm and cool uses. PIR has the following advantages over traditional insulation materials:

- Low thermal conductivity

- High compressive strength

- Fire-resistant characteristics

- Dimensional stability

- Long service life

Due to the above benefits, PIR Pipe Sections Manufacturers are rapidly offering solutions to industrial projects which require high performance and reliability.

Why Energy Efficiency Matters in Industrial Systems

Poorly insulated piping systems cause energy loss leading to increased operating costs, unstable conditions of processes and environmental impact. Industrial sites have piping systems that are long networks which carry steam, chilled water, chemicals and other fluids. Even the slightest form of heat loss during long distances can have a great effect in regard to total energy consumption. Enhanced PIR pipe sections minimize thermal transmission and benefit facilities:

- Maintain consistent process temperatures

- Reduce energy waste

- Lower operational expenses

- Improve system performance

- Meeting environmental compliance standards

Collaboration with reputable PIR Pipe Sections Manufacturers in India can help the industries to obtain insulation materials design to perform well over time on thermal performance.

Key Features of Advanced PIR Pipe Sections

- Superior Thermal Performance: PIR is also one of the lowest thermal conductivity values of rigid foam insulations. This implies improved heat retention of hot systems and enhanced cooling retention of the chilled systems. Less thermal loss is a direct proportionality to reduced fuel consumption or electricity consumption.

- High Structural Strength: Industrial piping is usually used in adverse conditions. PIR pipes sections give the pipe great compressive strength enabling them to resist mechanical stress and external load without deformation.

- Fire Resistance: PIR has improved the performance of fire over most of the traditional insulating materials. Its chemical composition gives it better resistance to spreading flames; hence it is applicable to risky industrial locations.

- Moisture Resistance: The intrusion of moisture may deteriorate the performance of insulation. The sections of the PIR pipes are highly resistant to getting absorbed into water and keep their ability to insulate the water as time goes by.

- Long-Term Durability: PIR has a stiff form, which facilitates dimensional stability, minimizing the shrinkage and keeping insulation tight around the pipe systems.

Such attributes have made PIR Pipe Sections Manufacturers significantly stakeholders in the development of infrastructure.

Energy Savings Through Thermal Efficiency

PIR pipe sections are mostly used to minimize heat transfer. Insulating pipes with hot fluids will reduce the loss of heat by a huge percentage. On the same note, refrigeration or chilled water is more efficient to maintain low temperatures. Saving energy is achieved by the following:

- Reduced boiler fuel consumption

- Lower compressor workload

- Stable process temperatures

- Reduced condensation in cold lines

- Improved equipment lifespan

The industrial plants which have partnered with the major PIR Pipe Sections Manufacturers in India usually show better energy performance during the extended period of operation.

Environmental Benefits

The direct contribution to the sustainability objectives is energy efficient insulation. Less energy consumption results in decreased emissions of greenhouse gases and better environmental repercussions. PIR insulation assists industries to shift to a greener operation by reducing their carbon footprint. Also, the usage of durable insulation materials will decrease the frequency of replacements which will lower the level of waste production. With industries becoming more environmentally friendly, the demand of the suppliers of PIR Pipe Sections Exporter in India is likely to increase in the foreign markets.

Installation Advantages

PIR pipe sections are pre-shaped and highly engineered and can be installed more easily. They are densely and uniformly shaped:

- Uniform coverage

- Reduced installation time

- Improved joint sealing

- Better fit around complex pipe networks

Thermal performance is also increased with professional installation. Seasoned PIR Pipe Sections Producers offer technological advice to assist consumers to get the best output.

Why Choose Us

Alaska PUF Industries has been unique in the insulation industry, owing to its focus on accuracy in production, uniformity of its products, and technical skills. The company has a lot of experience in the industry, and it provides high-performance PIR pipe sections adapted to operational environments that are strenuous. Being a reputable PIR Pipe Sections Exporter in India, Alaska PUF Industries has a high level of quality and superior production. Alaska PUF Industries is preferred by clients because of its reliable supply chain, tailor-made services, and commitment to providing insulator products that promote energy performance and operational excellence in various industries.

Conclusion

Advanced PIR pipe sections offer a powerful solution for industries aiming to enhance energy performance and reduce operational costs. Their low thermal conductivity, structural stability, moisture resistance, and fire performance make them ideal for diverse industrial applications. By investing in high-quality PIR insulation, businesses can improve temperature control, lower energy consumption, and support sustainable operations. Partnering with experienced PIR Pipe Sections Manufacturers in India allows industries to access durable and performance-driven insulation systems. As global energy standards evolve, PIR pipe sections remain a reliable choice for long-term efficiency and industrial excellence.

Boost Energy Efficiency with Advanced PIR Pipe Sections call +91 8141433999 or email info@alaskapuf.com.

Key Takeaways

- PIR pipe sections provide superior thermal insulation, reducing heat loss and improving energy efficiency in industrial piping systems.

- High structural strength and dimensional stability ensure long-term durability and resistance to mechanical stress.

- Fire-resistant and moisture-resistant properties make PIR pipe sections safe and reliable for demanding industrial environments.

- Pre-engineered design allows faster installation, uniform coverage, and better performance across complex pipe networks.

- Using PIR pipe sections lowers operational costs, reduces energy consumption, supports sustainability, and extends equipment lifespan.